An In Depth Guide to "TATENOKAWA"

Volume 8 looks at part 4 of the brewing process: Pressing, filtration, pasteurisation, bottling and storage. Similar to the previous volumes 6 and 7 this volume contains a lot of technical terms, the majority of which can be studied in more detail in the various books that are available.

Volume 8 - Brewing process Part 4: Pressing, filtration, Pasteurisation, Bottling and Storage Pressing and Filtration

Pressing and Filtration

In the pressing stage, a yabuta (automatic compressor) is used to divide the mash into solids (lees) and liquids (unprocessed sake). The yabuta is similar in shape to an accordion, comprising of a row of cloth-covered boards to which the mash is added that when air pressure is applied squeeze the liquid out through a small tap called a funaguchi. The pressing of a batch of sake can be split into 3 sections.

- Arabashiri (Lit:First Run-Off) : The first part of the pressing of a batch of sake.

- Nakadori (Lit: Middle-Cut) : The middle part of the pressing of a batch of sake.

- Seme : The third and final section of the pressing of a batch of sake.

Pasteurisation, Bottling and Storage:

Next, the sake is filtered and pasteurised. Pasteurising halts the activity of the koji enzymes and kills off any remaining yeasts and hiochi bacteria, which are basically a bad type of lactic acid bacteria that muddies the sake and defaces its aroma. Here at “TATENOKAWA” we use a plate heater to pasteurise the sake.

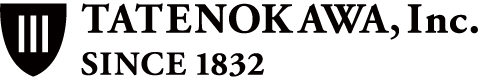

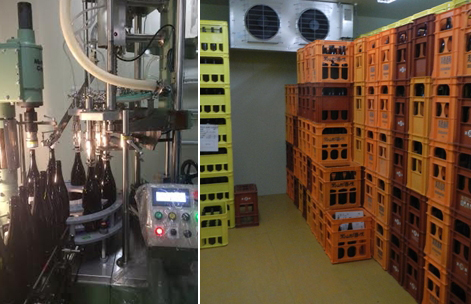

This type of heater has the merit of being able to rapidly heat up to 65 degrees and cool back down to 20 degrees, minimising any damage to the flavour and aroma of the sake. After pasteurising and cooling, in the interests of hygiene we use an automatic bottling machine to bottle the sake. We store the sake in bottles so that it is able to age at a much lower temperature, which makes for a more relaxed rounded flavour.