An In Depth Guide to "TATENOKAWA"

Volume 5 introduces Part 1 of the brewing process: Preparing the raw ingredients. Rice polishing and water for brewing.

Volume 5 - Part 1: Rice Polishing and Water for Brewing

About the Brewing Process

The key ingredients of sake are the staple of the Japanese diet rice, and water. Sake brewing exploits the various organisms invisible to the naked eye: yeasts, koji microbes and lactic acid microbes. The flow chart on the right shows the “TATENOKAWA” brewing process. Over the next 4 volumes we will explain what is special about our process and sets it apart from other breweries.

- Sake Production Part 1: Preparation of the Raw Ingredients, Rice Polishing, and Water for Brewing - covered in this volume.

- Sake Production Part 2: The koji and Yeast Starter→ Covered in Volume 6

- Sake Production Part 3: The Mash, Fermentation.→ Covered in Volume 7

- Sake Production Part 4: Pressing, Filtration and Pasteurisation, Storage in Bottles.→ Covered inVolume 8

This guide covers only the very basics of the traditional sake brewing process that “TATENOKAWA” employs. Should you wish to learn more about sake in general, various books are available.

Rice Polishing

The outer layers of a grain of sake rice contain lots of vitamins, proteins and fats, all of which produce off flavours in the end product. By polishing the outer layers away we are able to leave out these unwanted parts. “TATENOKAWA” makes only Junmai Daiginjo which requires at least 50% of the grain to be polished away. In 2013 the average amount remaining was as little as 47.5%. It takes between 30-36 hours to polish 1200kg of rice to 50%, and 70 hours to polish down to 18%. The by-product of this polishing process nuka (rice bran) is then sold on to be used in the production of rice oil and rice crackers.

Water for Brewing

The water used for sake brewing must contain few chemical components. Sake is made up of 80% water so the quality of the water can have a huge effect on the end flavour.

It is often said that where you find good water you will find sake. The water used in our brewing is soft water that originates from Mt. Chokkai, one of the 100 most famous mountains in Japan. The fact that the Shonai Region is mountainous means that it gets plenty of rain and snow which soaks into the soil and is filtered by the various layers of earth over years and months. Sake brewing requires up to 50 times the weight of the rice in water so it would be no exaggeration to say that sake is made with the blessing of Mother Nature.

Preparation of the Raw Ingredients

We interviewed our brewers about the preparation of the raw ingredients.

Q1: In what ways have you improved the washing and soaking process?

A1: The purpose of washing the rice is to remove any rice bran that may have stuck to it. We use a machine to ensure a consistent washing.

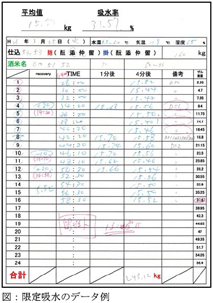

The purpose of the soaking stage is to absorb water into the rice. If the rice does not absorb the right amount of water it makes the later stages of production more difficult. Therefore, we record the data from each washing such as water temperature, air temperature, moisture levels, time required and use the results to determine how long the rice should be soaked for.

It is also important to develop an ability that allows you to judge by yourself without having to rely on machines or data. When it comes to new products, there is not yet any data to rely on so judgement is a result of careful observation. Even a deviation of 1% from the intended absorption rate can lead to very big problems further down the line. There is no room to start again so we have to get it right first time.

Q2: In what way have you improved the steaming process?

A2: The rice is steamed in a wagama (an iron pot) and koshiki (vat). The steam circulates around the brewery creating a magical atmosphere. The most important points of steaming are as follows.

- Use the right amount of water - This is determined based on past experience.

- We commence the steaming process 55 minutes after the steam has started to escape - determined based on past experience.

- Sham rice is put under the rice- this way the steam does not make actual contact with the rice preventing sticky rice.

- In 2014 we installed a super heater into the kama. - as a result the vapour dries quickly (reducing the amount of sticky rice)

Q3: In what way have you improved the cooling process?

A3: As the saying goes, the 123s of good sake brewing are 1. koji, 2. yeast starter, 3. mash. The koji and yeast starter stages are particularly important so the rice intended for these stages is prepared by hand: taking great care not to crush the rice we lay it out uniformly and let it cool naturally. The rice intended for all 3 stages of the mash is cooled using a machine called a houreiki.