An In Depth Guide to "TATENOKAWA"

Volume 6 introduces Part 2 of the brewing process: Koji and yeast starter.

Volume 6 - The Brewing Process Part 2: Koji and Yeast Starter

Koji

Koji is steamed rice that has had koji-kin (LIT: koji-microbe)— a type of mould— cultivated onto it. It is largely responsible for determining the flavour of the end product. Although the key ingredient of sake is the rice, rice alone is not enough to make alcohol. Therefore, it is first necessary to turn the starch in the rice into a form of glucose. This process is called saccharification. The koji performs 3 main roles; the biggest of which is to produce enzymes.

- Provide enzymes that dissolve the steamed rice and facilitate saccharification.

- Provide nutrients for the yeast starter: vitamins and amino acids.

- Provide the ingredients for flavour and aroma.

We interviewed the brewers to learn more about the koji making process and find out what they consider to be the most important points.

Q1: What are the first steps of the process?

A1: After the rice has finished cooling and reached a state where it is hard on the outside but soft on the inside, it is time for tanekiri: the stage where we sprinkle koji-kin (koji microbe) onto it. The rice is laid out onto a bed called a toko and the koji applied. After waiting a short while for the koji spores to land on the steamed rice, we then knead the steamed rice together in a step called tokomomi: repeating the first steps and applying a second layer of koji-kin so that the rice receives an even coating. Next after forming the rice into rice cake shapes, we leave it to rest for 24 hours.

Q2: In what ways have you improved the various stages of the process: Mori, nakashigoto, shimaishigoto and dekoji?

A2: Allow us to describe each part of the process individually.

Mori: 24 hours after tanekiri, the koji, in its rice cake-shaped form, will have hardened and white koji-kin will have started to grow on its surface, at which point it is broken up and heaped into koji bako (LIT: koji boxes). The malt is divided up into smaller piles to increase the mass and to facilitate a gradual increase in temperature; this also stops too much moisture from escaping at once.

Naka Shigoto・Shimai Shigoto: Once the temperature of the koji has increased, it is time for the next step nakashigoto: we mix the koji thoroughly to ensure an overall equal temperature and to allow it to breathe. Finally, we bring everything together again to reduce the mass. A short while after nakashigoto, the temperature will be over 40 degrees, at which point we begin shimaishigoto. The aim of this stage is to equalise the overall temperature and to start evaporating moisture from the steamed rice. Once the outer part of the rice is dry, the koji will be attracted to spread its legs into the centre, where there is moisture available. Koji that has been penetrated right to the centre by the koji-kin is called tsukihazekoji.

Dekoji: Once the koji has maintained a temperature over 40 degrees for at least 12 hours the process is complete — The koji intended for the yeast starter and first stage of the mash is allowed slightly more time; the koji intended for the second and final stages of the mash is allowed slightly less. The koji is moved to the drying area where it is then laid out to halt the cultivation process. It remains there until it is required for the mash the following day.

Yeast Starter

The yeast starter (shubo or moto, LIT: The mother / origin of sake) is a cultivation of a healthy yeast made with a mixture of water, koji and steamed rice that is propagated several times before being transferred to the mash. It is a very important stage of the brewing process. Here at “TATENOKAWA” we use the Sokujo (quick start method) so the yeast starter is normally completed within 13 days. We interviewed our brewers to learn more about the process and find out what they consider to be the most important points.

Q1: In what ways have you improved the yeast starter process?

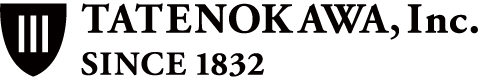

A2: Allow me to explain each day of the 13-day process.

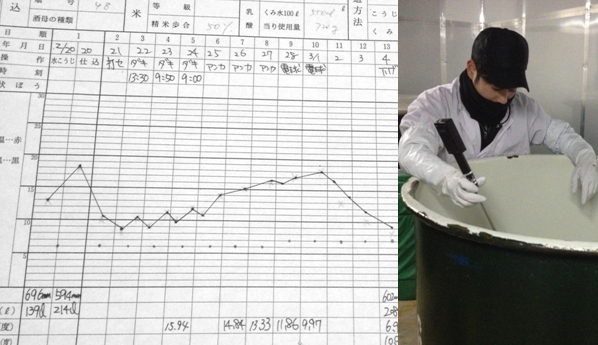

Day 1: We start with a type of yeast starter called mizukoji (LIT: liquid koji) made with water prepared the day before, lactic acid and koji. When we add the koji the temperature should ideally be 13 degrees. To this we add the steamed rice. The steamed rice needs to be around 18 degrees at this point so we have to cool it, which we do by hand, mixing it to help equalise the temperature and because the rice has become heavy by absorbing moisture. This process is called tekai (LIT: hand paddling). The process up to this point is referred to as motodate. After about 3 hours has passed, a steel cylinder is inserted and water filled with koji enzymes seeps into it. We scoop out this enzyme liquid every 2 hours and add it back to the surrounding mixture from the top. By adding back from the top we ensure an even concentration.

Day 2: The next morning, the steel cylinder is removed - The starter is not interfered with for the rest of the day. This process is called utase. The purpose of this stage is to reduce the temperature as much as possible to control the action of the yeast.

Days 3-5: Using a device called a dakitaru, the starter is heated up to facilitate saccharification. It is now the koji's time to work. The liquid enzymes break down the starch molecules and turn them into a form of glucose: food for the yeast.

Days 6-9: We use a bulb and a heater to heat up the starter and facilitate alcohol conversion. It is now the yeast's time to work. The bulb enables us to keep the same temperature.

Day 10: Depending on the results of our analysis, we will stop heating the starter. A lid is added which causes the temperature to decrease steadily.

Days 11-12: Actually not much happens on this day. We simply leave the yeast starter to do its job, lowering the temperature if necessary to make sure it doesn't tire out.

Day 13: Using the sokujo method, the starter is normally ready in around 13 days. Once ready, the starter is moved from the small tanks to bigger fermentation tanks. Most of the time we use a pump to do this except for starters made with higher polished rice: polished to between 18% and 40%, which are instead moved by hand using wooden buckets.